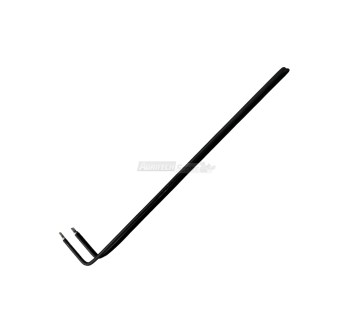

Electric Motor for Rotisserie | Gear Motor with M8 Threaded Connection

This "Made in Italy" Motor-Gearbox for rotisserie, thanks to its minimal absorption, can also be used with an inverter by connecting it directly to the car's battery.

| Technical Features: |

| Max Power Absorbed |

30 Watt |

| Diet |

220 Volts / 50 Hz |

| Turns |

2/min. |

| Flow rate |

Kg. 40 |

| Attack: |

male |

M 8 threaded |

| Measures |

130x100x |

100mm motor only |

| with 130 mm connection |

| Weight |

Kg. 1.80 |

What is the function of the electric rotisserie motor:

The electric motor in a rotisserie plays an essential role in ensuring that food is cooked evenly. This component is responsible for the constant and controlled rotation of the spit on which food, such as chicken, roasts or other types of meat, are skewered.

Rotation allows heat to reach all surfaces of the food evenly, preventing some parts from overcooking while others remain raw. This results in even cooking and optimal browning. The electric motor is designed to operate at a constant speed, which is crucial to maintaining a stable rotation rate that ensures uniform heat distribution. In addition, the quiet and efficient operation of the motor contributes to a pleasant and uninterrupted cooking experience.

In short, the electric motor is the heart of the rotisserie, determining the final quality of the dishes prepared and ensuring that every meal is cooked to perfection.

How a gearmotor is made

A gearmotor is an essential component in motor systems such as rotisserie motors , as it combines an electric motor with a speed reducer. This combination allows for a lower output speed and higher torque than the motor alone would provide.

The structure of a gearmotor begins with the electric motor, which can be direct current (DC) or alternating current (AC), depending on the specific application. The motor is connected to the gearbox through a drive shaft. The gearbox consists of a series of gears, usually planetary or worm gears, which reduce the angular speed of the motor and increase the torque available at the output. The body of the gearmotor is usually made of metal for strength and durability, while the gears can be made of metal or composite materials to reduce noise and wear. Internal lubrication helps maintain optimum performance and prolong the life of the device. In rotisserie motors, the gearmotor allows the spit to rotate at a constant and controlled speed, ensuring even cooking of the food. Due to its efficiency and reliability, the gearmotor is essential to improving the performance of rotating devices such as rotisseries.

What motor to use for rotisserie

When choosing a rotisserie motor, it is essential to consider several factors to ensure efficient and safe operation. First, the power of the motor is a crucial element ; for domestic applications, a motor with a power of between 15 and 30 watts is usually sufficient. However, for professional uses or heavier loads, a more powerful motor may be necessary. Another important aspect is the rotation speed. A good rotisserie motor should offer a constant speed, usually between 2 and 3 revolutions per minute (RPM), to ensure even cooking of the meat. The load capacity is also essential: the motor must be able to support the weight of the meat without excessive strain. For this reason, it is advisable to choose a model with a load capacity greater than the maximum expected weight. Finally, durability and resistance to high temperatures are key characteristics. Motors made of heat-resistant materials and with protection against humidity ensure a long operating life. Considering these elements, you can choose the right motor that meets your specific rotisserie needs.

Gearmotor-Electric Motor for Rotisserie with threaded connection or 12x12 mm or 8x8 mm square connection, all available on our Agritechstore website